|

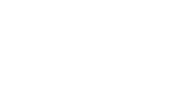

Application:

Sub sea valves

Oil & natural gas field

Chemical fields

Process:

CNC machining

VMC thread milling

Cross holes drilling

Linishing / polishing |

|

Application:

Sub sea valve

Oil & natural gas field

Chemical fields

Process:

CNC machining

VMC thread milling

Cross holes drilling

Linishing / polishing |

|

Applications:

Sub sea valves Oil & natural gas field Chemical fields

Process:

CNC Machining Linishing / polishing |

|

Application:

Sub sea valves Oil & natural gas field Chemical fields

Process:

CNC Machining

VMC Machining

Cross holes drilling

Linishing / polishing

|

|

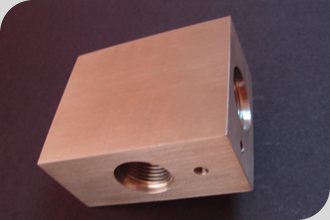

Application:

Sub sea valve

Oil & natural gas field

Process:

CNC machining

Cross holes drilling

Assembly hydrostatic pressure testing 15,000 psi |

|

Application:

Steam boiler plants

Process:

CNC machining

Holes drilling / tapping

Material:

Carbon / alloy / stainless steel |

|

Application:

Sub sea valve

Oil & natural gas field

Process:

CNC machining

Cross holes drilling

Assembly , hydrostatic pressure testing to 15,000 psi |

|

Application:

Steam boiler plants

Process:

CNC machining

Cross holes drilling

Assembly

Hydrostatic pressure testing 210 bar (kg/cm2)

Material:

Carbon / alloy / stainless steel |

|

Application:

Paddle valves

Process:

CNC machining

Serration rolling

Material:

Stainless steel |

|

Application:

Truck / bus power steering

Process:

CNC machining

Holes drilling / tapping

Material:

Alloy steel |

|

Application:

Truck / bus power steering

Process:

CNC machining

Holes drilling / tapping

Material:

Alloy steel sae 8627h |

|

Application:

Truck / bus steering

Process:

CNC machining

Tubes slots punching

Powder coating

Material:

Carbon steel En3D |

|

Operation on HYDRAULIC PRESS BRAKE 1850 TONS

Capacity:

9300 MM LENGTH mm 17MM THK PLATE CAN BE BENT TO PROFILE

Ex: POLYGON TOWER PLATES BENDING |

|

Welding with 100% UT qualification

No of joints 4 or 5 |

|

Application:

Boilers steam flow control

Process:

CNC shearing

Fit up and welding using fixtures

Assembly and Painting

Material:

Carbon steel |

|

17 M long welded beams

for BHEL |

|

View of finished coal compartment assemblies waiting for despatch to sites.

Coal nozzle tips made of stainless steel plates and welding with SS 309 electrodes |

|

Application:

Boiler plant

Process:

CNC shearing

Rolling of shell and perforated sheet

Welding CO2/ TIG

Fit up and assembly

Wool packing

Aluminum (HR 600°C) spray painting

Packing

Material:

SS 304/Carbon steel, LG Mineral wool, SS/MS wire mesh, Fiber glass cloth, SS Perforated sheet |

|

Application:

Boilers

Process:

CNC band saw cutting

CNC machining

Thread rolling

Plating

CO2 welding

Assembly and testing

Painting

Material:

Carbon steel, Spring material |

|

One of the boiler products is manufactured with CNC profile cutting and forming, drilling Tapping process. Length up to 17 Mtrs can be processed. |

|

Wind box for BHEL weighing up to 35.5 Tons as a single largest fabricated part. The length of this structure is up to 17.6 Meters. Raw material is supplied by Customer and is converted as a product. |

| |

|

| |

|